summary

Boiling dryer, also known as fluidized bed, has been continuously improved and enhanced since its application for more than 30 years. It is widely used in industries such as pharmaceuticals and grain processing, such as dehumidification and drying of raw materials, granular medicines, granules, feed, plastic resins, and other powdered and granular materials. The particle size of the material can range from 0.1-6mm, The optimal value is 0.5-3rnm.

Principle and characteristics

Clean hot air is distributed into the bed through the valve plate, and the wet material entering from the feeder is fluidized by the hot air. For example, boiling water jumps in the bed, so it is called a boiling dryer (or machine). Due to the wide contact between the hot air and the material, it can be dried in a relatively short time. Entering from one end of the bed, after several minutes to tens of minutes of boiling, it automatically flows out from the other end of the bed. Steam or electric heating can also be used, and hot air can be directly obtained from a fuel (or coal-fired) hot air stove. It can implement automated production and is a continuous drying equipment. Fast drying speed, low temperature, can ensure production quality, and meet the GMP requirements for drug production.

Main technical parameters

干燥能力

外形尺寸 長x寬x高

風機

進風溫度

出料溫度

加熱耗能

功率(KW)

風壓(Pa)

風量(m'/h)

蒸汽(kg/h)

電(kw)

20-25

2600x800x2800

11

7100

3600

60-140

40-80

100

60

2600x800x3000

11

7100

3600

100

60

30-45

2600x1000x2800

22

7400

7100

200

120

2600x1000x3000

22

7400

7100

200

120

50-80

5000x1200x3300

55

8600

13500

400

240

5000x1200x3500

55

8600

13500

400

240

120-150

6000x1200x3300

75

9300

18400

600

360

6000x1200x4000

75

9300

18400

600

360

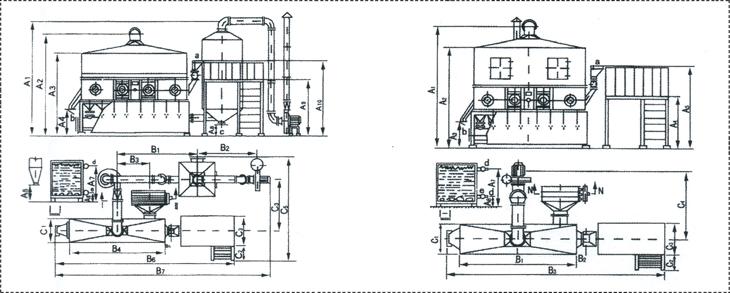

XF-A series installation diagram XF-B series installation diagram

XF-A series size reference table

|

model |

A1 | A2 | A3 | A4 | A5 | A6 | A7 | A8 | A9 | A10 | B1 | B2 | B3 | B4 | B5 | B6 | B7 | C1 | C2 | C3 | C4 | C5 |

|

XF-10A |

3500 | 2800 | 2300 | 700 | 700 | 120 | 900 | 600 | 1400 | 2200 | 1700 | 1900 | 500 | 1500 | 110 | 4000 | 4700 | 700 | 700 | 1200 | 2000 | 4000 |

|

XF-20A |

4110 | 3100 | 2500 | 800 | 800 | 120 | 900 | 600 | 1600 | 2400 | 1900 | 2200 | 650 | 2000 | 110 | 4660 | 5900 | 800 | 800 | 1500 | 2200 | 4745 |

|

XF-30A |

4750 |

3500 | 2700 | 800 | 800 |

120 |

900 |

650 |

1600 |

2400 |

2200 | 2200 | 1200 | 2500 | 130 | 5100 | 6000 | 1000 | 1000 | 1800 | 2500 | 5400 |

|

XF-50A |

5000 | 3900 | 3500 | 800 | 800 |

120 |

900 |

700 |

1800 |

2600 | 2700 | 2500 | 1700 | 3000 | 150 | 6200 | 6500 | 1200 | 1200 | 2000 | 2800 | 6000 |

XF-A series interface table

|

model |

a | b | c | d | e | f |

|

Feeding |

Discharge |

Discharge |

Steam inlet |

Water cooling outlet |

Discharge | |

|

XF-10A |

300x400 |

60x120 |

320x320 |

Dg20 |

Dg20 |

?150 |

|

XF-20A |

320x430 |

60x120 |

320x320 |

Dg20 |

Dg20 |

?150 |

|

XF-30A |

350x450 |

120x240 |

320x320 |

Dg25 |

Dg25 |

?200 |

|

XF-50A |

400x480 |

120x240 |

320x320 |

Dg40 |

Dg25 |

?200 |

|

model |

A1 | A2 | A3 | A4 | A5 | A6 | A7 | B1 | B2 | B3 | C1 | C2 | C3 | C4 |

|

XF-10B |

3000 | 2300 |

800 |

1400 | 2200 |

120 |

900 |

1500 | 110 | 4000 | 700 | 700 | 1300 | 3000 |

|

XF-20B |

3300 | 2400 |

800 |

1600 | 2400 |

120 |

900 |

2000 | 110 | 4600 | 800 | 800 | 1500 | 3500 |

|

XF-30B |

3500 | 2800 |

800 |

1600 |

2400 |

120 |

900 |

2500 | 130 | 5100 | 1000 | 1000 | 1800 | 3900 |

|

XF-50B |

3900 | 3100 |

800 |

1800 | 2600 |

120 |

900 |

3000 | 150 | 6200 | 1200 | 1200 | 3000 | 4500 |

XF-B series interface table

|

model |

a | b | c | d |

|

Feeding |

Discharge |

Discharge |

Steam inlet |

|

|

XF-10B |

300x400 |

60x120 |

320x320 |

Dg20 |

|

XF-20B |

320x430 |

60x120 |

320x320 |

Dg20 |

|

XF-30B |

350x450 |

120x240 |

320x320 |

Dg25 |

|

XF-50B |

400x480 |

120x240 |

320x320 |

Dg40 |

If you have any questions, please call the number below to express your opinions and needs, so that we can serve you in a timely manner.

400-8815-806 Read more

Address:No. 111 Xinzhuang Road, Zhutang Town Industrial Park, Jiangyin City, Jiangsu Province

Address:No. 111 Xinzhuang Road, Zhutang Town Industrial Park, Jiangyin City, Jiangsu Province

Tel:+86 510-86006569

Website:www.danutterstrom.com

E-mail:13961632622@163.com