summary

PA vacuum dryer is widely used in the chemical industry, especially in the organic semi-finished products and dye manufacturing industry. It uses steam or thermal oil or hot water to enter the jacket to indirectly heat the materials, and dehumidifies them under vacuum. Therefore, it is particularly suitable for drying materials that are resistant to high temperatures and easily oxidize at high temperatures, as well as drying materials that are prone to dust and solvents that need to be recovered during the drying process. This machine has a compact structure, simple operation, stable and reliable performance, and a long maintenance cycle. It has been proven through long-term production practice that it can dry powders, granules, pastes, adhesives, and even solutions under appropriate conditions at high or low temperatures.

Application scope: Suitable for drying materials in industries such as medicine, food, and chemical industry; Suitable for slurry, paste, and powder like materials; Heat sensitive materials that require low-temperature drying; Easy to oxidize, explosive, highly irritating, and highly toxic materials; Require the recovery of materials containing organic solvents.

Principle and characteristics

Principle:

1. This machine adopts a sandwich heating method, with a large heat transfer surface and high thermal efficiency;

2. This machine is equipped with stirring to form a continuous circulation state of materials in the cylinder, further enhancing the performance;

3. Heat sensitive materials that require low-temperature drying; Higher uniformity of material heating;

4. This machine is equipped with stirring, allowing for smooth drying of slurry, paste, and paste materials.

5. The mixing device of this machine adopts castings, which can increase the transmission torque.

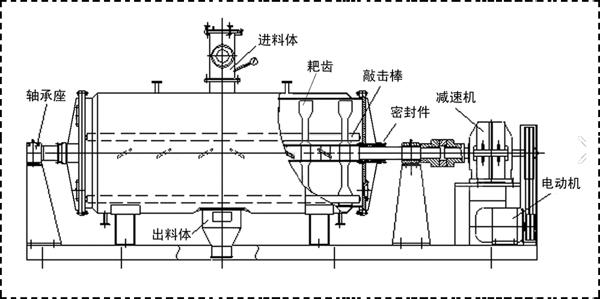

Features: The PA dryer mainly consists of a shell, a rotating shaft, and rake teeth. Unlike paddle dryers, The rotating shaft and rake teeth of the PA dryer are not used as heating surfaces, but only for stirring materials and updating the surface. The rake dryer is vacuum operated. Firstly, wet materials are added to the dryer, and heating medium (usually steam or hot water can also be used as thermal oil) is introduced into the jacket. Then, the vacuum pump is started, and after reaching the specified vacuum degree, the mixing device is started. By using the forward and reverse rotation of the rake teeth, the material is continuously pushed towards the middle and both ends during the drying process. At the same time, four stainless steel rods (seamless steel pipes) can be placed between the rake teeth according to user requirements. It continuously moves up and down during the shaft rotation, vibrating and bonding the material on the wall of the dryer. And by crushing the agglomerated materials, these measures can ensure timely updating of the heat transfer surface, thereby accelerating the rate of heat and mass transfer, When the material is dried to a fixed moisture content, stop heating, turn off the vacuum system, take out the dried material, and complete a cycle of operation. This type of dryer is suitable for drying slurry, paste, granular, and fibrous materials, especially for heat sensitive materials and drying operations that require the recovery of organic steam. The vacuum rake dryer has many advantages. The rake teeth of the vacuum rake dryer have two basic forms: left and right. Both are irregular and blade shaped. When installed, the adjacent rake teeth have a 90 degree difference in orientation, and irregular rake teeth are installed at both ends of the shaft, while blade shaped rake teeth are installed at the rest. When the shaft rotates, the material first moves to both sides and then to the middle under the action of the stirring shaft, which can ensure that the material is in a uniform stirring state throughout the entire drying process. The commonly used drying medium for vacuum rake dryers is steam, thermal oil or hot water with a pressure of 0.1-0.3 MPa.

Main technical parameters

project

model

name

unit

ZPG-500

ZPG-750

ZPG-1000

ZPG-1500

ZPG-2000

ZPG-3000

ZPG-5000

Working volume

L

300

450

600

900

1200

1800

3000

Same size inside

MM

300*1500

800*1500

800*2000

1000*2000

1000*2600

1200*1500

1400*3400

Mixing speed

RPM

1-15

1-12

1-10

1-6

power

KW

4

5.5

5.5

7.5

11

15

22

Sandwich design pressure

MPA

≤0.3

Internal pressure

MPA

-0.09到-0.096

If you have any questions, please call the number below to express your opinions and needs, so that we can serve you in a timely manner.

400-8815-806 Read more

Address:No. 111 Xinzhuang Road, Zhutang Town Industrial Park, Jiangyin City, Jiangsu Province

Address:No. 111 Xinzhuang Road, Zhutang Town Industrial Park, Jiangyin City, Jiangsu Province

Tel:+86 510-86006569

Website:www.danutterstrom.com

E-mail:13961632622@163.com