summary

Spray drying is the most widely used process in liquid forming and drying industries. LPG series high-speed centrifugal spray dryer is most suitable for generating powdery and granular solid products from solution, lotion, suspension and pumpable paste liquid raw materials. Therefore, spray drying is a very ideal process when the particle size distribution, residual water price content, bulk density and particle shape of the finished product must meet accurate standards

Principle and characteristics

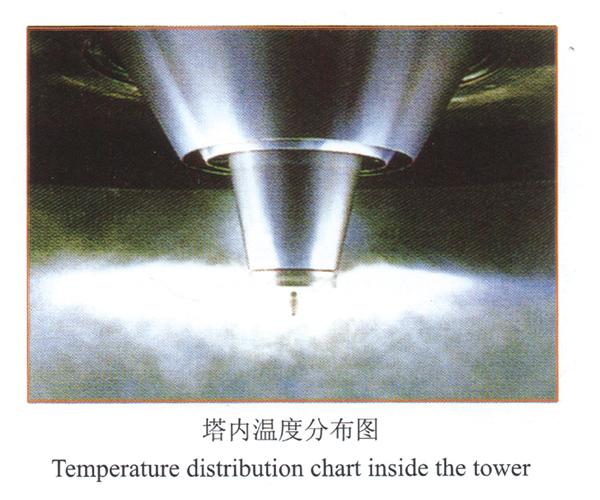

The air of LPG series high-speed centrifugal spray dryer is filtered and heated, and enters the air distributor on the top of the dryer. The hot air enters the drying chamber in a spiral shape evenly. The feed liquid is sprayed (rotated) by the high-speed centrifugal atomizer on the top of the tower body to form extremely fine droplets, which can be dried into finished products in a very short time. The finished product is continuously discharged from the bottom of the drying tower and the cyclone separator, and the exhaust gas is discharged by the fan. Features:

1. LPG series high-speed centrifugal spray dryer has a fast drying speed. After atomization, the surface area of the feed liquid is greatly increased in the hot air flow, and 95% -98% of the water can be evaporated instantly. It takes only a few seconds to complete the drying. It is especially suitable for drying heat sensitive materials.

2. LPG series high-speed centrifugal spray dryer products have good uniformity, fluidity and solubility, high purity and good quality.

3. The production process of LPG series high-speed centrifugal spray dryer is simplified, and the operation and control are convenient. For liquids with a moisture content of 40-60% (up to 90% for special materials), they can be dried into powder products in one go, without the need for crushing and screening after drying. Reducing production processes, improving product purity, and adjusting and managing product particle size, bulk density, and moisture within a certain range through changing operating conditions are all very convenient.

Drying process diagram

Main technical parameters

Steam+electricity, fuel oil, gas, hot air stove

model

LPG-5

LPG-25

LPG-50

LPG-100

LPG-150

LPG-200-2000

Inlet temperature (℃)

140-350 (self-control)

Export temperature (℃)

80-90

Maximum evaporation of water (kg/h)

5

25

50

100

150

200-2000

Speed (r/min)

25000

18000

18000

18000

1500

8000-15000

Spray disc diameter (mm)

50

120

120

140

150

180-240

Electric heating power (kW)

9

36

63

81

99

heat source

Electricity

Steam+Electricity

External dimensions (length x width x height) m

1.8x0.93x2.2

3x2.7x4.26

3.5x3.5x4.8

4.6x4.2x6

5.5x4x7

Based on actual situation

Dry powder recovery (%)

≥95

If you have any questions, please call the number below to express your opinions and needs, so that we can serve you in a timely manner.

400-8815-806 Read more

Address:No. 111 Xinzhuang Road, Zhutang Town Industrial Park, Jiangyin City, Jiangsu Province

Address:No. 111 Xinzhuang Road, Zhutang Town Industrial Park, Jiangyin City, Jiangsu Province

Tel:+86 510-86006569

Website:www.danutterstrom.com

E-mail:13961632622@163.com